Plasma transferred arc (PTA) hard-facing is a versatile method of depositing high-quality metallurgically fused deposits on relatively low-cost surfaces. Soft alloys, medium and high hardness materials, and carbide composites can be deposited on a variety of substrates to achieve diverse properties including wear and corrosion resistance at ambient or elevated temperatures. PTA hard-facing has several significant advantages over traditional welding processes such as oxyfuel (OFW) and gas tungsten arc (GTAW) welding.

Application

- Repairs on tool steels, rebuilding of cutting edges, forging, stamping dies, aluminium die casting moulds

- Repairs on cast iron, glass moulds

- Feeding screws repairs

- Hard-facing on drilling tools, valve seats and valves, mining machinery, milling tools

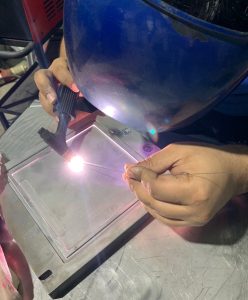

Micro-Plasma

Micro-Plasma is ideal for welding applications that require precision, high-quality layer quality and low dilution; in particular when fully automatic welding is impractical or inapplicable due to low numbers or the diversity of the tasks. With all these advantages, the CAP procedure is predestined for work that requires extra precision, low heat generation and minimal distortion (1 to 50Amp max.). The CAP technology also provides exceptionally high purity and quality of the welding seam from the very first layer.

Application

- Microplasma brazing

- Repairs on tool steels, the rebuilding of cutting edges

- Medical instruments welding

- Filter inserts welding, diaphragms and metallic meshes

- Repairs on plastic injection moulds

- Repairing on critical parts without heat treatment