Quality Management System

I-Spray has an effective quality management system that controls its job planning and execution in meeting customer requirements.

From its repair, refurbishing and reverse engineering processes, including high integrity testing I-Spray is able to meet its customers’ high standards and specifications. In I-Spray, we take the philosophy of “RIGHT FIRST TIME” seriously and continuously cultivate the culture which ultimately benefits both the company and the customers.

I-Spray’s certifications:

Quality Control

I-Spray’s product quality is maintained or improved to enhance customer satisfaction. This is done through continuous training, creating benchmarks and testing products to eliminate defects.

Quality control instruments used

Dial gauge

Vernier Calliper

Micrometer

Bore gauge

Depth gauge

Substrate temperature sensor

Surface profile test

Surface roughness test

Coating thickness gauge

Coating Adhesion Tester

Environmental and humidity meter

Portable Hardness Tester

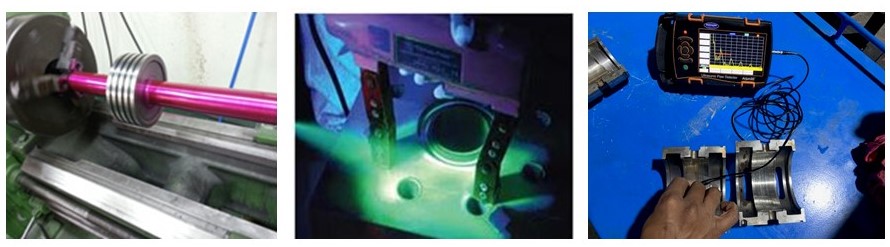

Surface NDE method such as Penetrant Test (PT), Magnetic Particle Test (MT) and Ultrasonic Testing (UT) are used to detect coating or welding imperfection that symbolise premature failure likely to occur if necessary prevention or rework steps have not been taken.